| |

closing the valve, as necessary. The fault

normally is stoppage in the trap, strainer, or

drainpipe. To eliminate this condition, close the

steam valve, remove the steam-trap strainer

basket, and clean it by scraping out the solids and

washing the basket until the mesh or perforations

are open and clear. Clean the pipe connection in

the steamer compartment, reassemble the

strainer, and repeat the pressure cooking. If there

is still no drip, the steam trap is at fault, so report

this to the engineer officer via the chain of

command.

After each meal, the steamer should be brush-

scrubbed, washed clean with hot soapy water,

and rinsed with hot water (170°F) and allowed to

air dry.

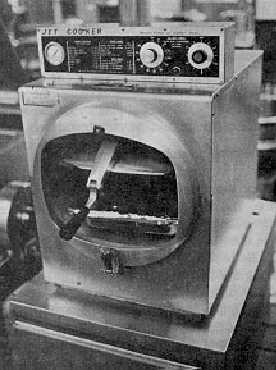

HIGH-COMPRESSION STEAMER

The high-compression steamer (fig. 4-10) is a

modular unit that is used to defrost and cook food

by using high-velocity steam. When steam enters

the unit, it is piped to a jet box from which it is

jetted directly onto the frozen food at

approximately 200 miles per hour (mph). The

steam gains the high velocity by being forced

through a series of small perforations.

48.132

Figure 4-10.—High-compression steamer

Operation

Check the steam supply gauge; 15 psi is needed

for proper operation. Insert foods into the cooking

chamber; then place the frozen food directly under

the jet box; close and seal the door. Select the time

(from 5 to 60 minutes) for the food to be cooked.

Turn the selector switch to 60 minutes and then

back to the desired cooking time. The pilot light

indicates that cooking is in progress. Food is

defrosted and cooked auto-matically. The pressure

gauge rises to approxi-mately 5 psi and increases to

15 psi after 2 minutes, where it will stay until

cooking has been completed. The door must be kept

locked until the cooking cycle has been completed.

All steam will exhaust automatically and the buzzer

will sound when the cooking cycle has been

completed.

Care and Cleaning

The steamer should be cleaned at the end of each

day that it has been used. To clean the jet steamer,

remove the jet plate, pan supports, and door,

including the gasket around the door, and wash in

warm soapy water. Rinse well in warm water.

Scrub the interior of the cylinder with warm soapy

water and rinse well.

The door gasket must be kept clean at all times.

With normal closing and locking of the door

assembly, a steamtight seal should be made

between the door gasket and the door opening. This

seal cannot be maintained if particles of foreign

matter are allowed to accumulate upon either of the

contacting surfaces.

If leakage of steam occurs, the door assembly is

improperly adjusted and a readjustment must be

made to the adjustment screw.

VENTILATOR HOODS

Ventilator hoods, like people, come in a

variety of shapes, sizes, and appearances, and

vary in their effectiveness from barely acceptable

to highly efficient. The filter-type hoods fall

into the barely acceptable category, and the

filterless grease extractors–mostly known as

Gaylord ventilators–are the most efficient. Filter-

type hoods are the hardest to keep clean and

are gradually being re-placed as funds allow.

They generally have no built-in fire protection

system. If the filters are not replaced after cleaning,

a buildup of grease deposits in the exhaust duct

system could lead to a fire! Depending upon the

type of fumes exhausted and the amount of use, the

filter should be removed and washed in the

dishwasher or deep sink daily, or no less than once

4-13

|