| |

detailed description of each item and stock numbers of

substitute items. It also includes illustrations and

diagrams of many types of material. The ASG is printed

in six different sections. You still must use the ML-N to

check for unit price, current NSN, and unit of issue.

Consolidated Master Cross-Reference List

The Consolidated Master Cross-Reference List

(C-MCRL) is a consolidated list of all NSN items of

supply in the FSC system. Consequently, it includes

many NSNs that are not listed in the ML-N. The

C-MCRL is distributed annually to Navy users. The

C-MCRL is made up of two parts. Part I crosses both

reference numbers and CAGE numbers to NSNs. Part

II crosses NSNs to both reference numbers and CAGE

numbers.

DETERMINING STOCK LEVELS

The determination of stock levels for individual

items depends on whether the item is SIM or non-SIM.

This section focuses on the manual SIM computation.

SIM ITEM COMPUTATION OF

DEMAND-QUARTERLY

The demand quantities entered in the Issues column

of each SIM stock record during the past 6-month,

9-month, or 12-month period are totaled. Based upon

the total quantity determined for the demand period, the

high limit, low limit, and safety level (HL/LL/SL)

quantities in each SIM stock record will be adjusted, as

necessary, to reflect the quantities authorized in the

appropriate average endurance table as illustrated in

figure 8-6. Computation of the total demand quantity

will be more frequent, if necessary, to reduce the

possibility of stock shortages or excesses. Periods of

unusual demand will be excluded from the demand

period. Quantities issued during an unusual demand

period will be excluded from the computation of the

total demand quantity. In determining the total demand

quantity, inventory and survey losses of missing

material will be included; inventory and survey losses

of on-hand material unfit for either issues or transfers

will not be included. When computing the total demand

quantity in stock records that reflect a unit of issue

change such as PR to EA or EA to DZ, any issue

quantities posted before the change must be converted

(in the count, not on the stock record) to quantities that

correspond with the current unit of issue. The demand

period used, the total demand quantity determined, and

the revised HL/LL/SL quantities should be made in

pencil because of the frequent changes normally

required.

Assuming a prescribed average endurance level of

75 days and an order and shipping time (O&ST) of 30

days, the revised data entries in figure 8-6 should be used

as follows:

If the total quantity issued from 18 April to 17

October 1993 (6 months) equals 20; then, for a 75-day

average endurance and a 6-month demand period, figure

8-6 indicates 14 as the high limit, 10 as the low limit,

and 7 as the safety level. When the quarterly

computation of demand results in a total demand

quantity that is not listed in the average endurance table,

the appropriate HL/LL/SL quantities can be determined

by:

l selecting two (or three, if necessary) of the listed

demand quantities that, when combined, equal the total

demand quantity determined from the stock record; and

then

l adding the HL/LL/SL quantities for each demand

quantity selected.

For example, assuming a prescribed average endurance

of 75 days, an authorized O&ST of 30 days, and a

6-month demand period, the HL/LL/SL quantities

authorized for a total demand quantity of 35 can be

determined from the table as follows:

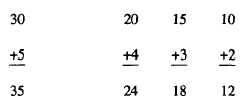

Listed

demand

quantities

HL LL

SL

When the average endurance tables for 9-month and

12-month demand periods are used for determining the

HL/LL/SL quantities authorized, a quantity of one for

each additional 3-month period must be added to each

of the totals derived by the method described in the

above computation. Per OPNAVINST 4441.12, the

range and depth of allowance material may be changed

at the shipboard level under stockage criteria prescribed

by approved shipboard procedures. Such procedures are

authorized by fleet commanders in chief for use of

variable operating and safety levels and for intensive

inventory management of special items.

8-13

|