| |

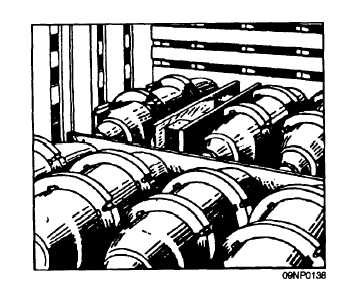

Figure 14-12.—Dunnage used to fill space.

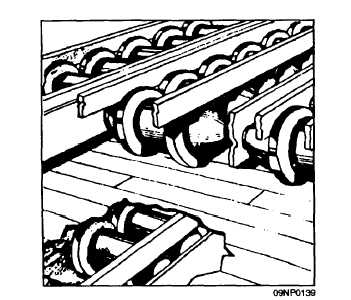

EQUALIZES PRESSURE—Figure 14-13

illustrates how dunnage is used in “flooring off’ to

distribute the weight of cargo in succeeding layers.

CRIBBING—Cribbing consists of beams formed

into a framework to provide support to heavy equipment

or other material.

PERMITS DRAINAGE—When laid athwart-

ships or fore and aft, according to the design of the

ship, dunnage permits water to flow into the drainage

system.

PROVIDES VENTILATION—When laid

athwartships or fore and aft, according to the design of

the ship, dunnage provides circulation of air through the

cargo.

Figure 14-13.—Flooring off.

BULKHEAD—Dunnage makes a good bulkhead

against a tier of cargo. Since the bulkhead will provide

considerable stability to the cargo, suitable bracing must

be installed.

CHOCKING AND BRACING—Dunnage can be

used to chock and brace heavy machinery and crates to

prevent shifting. Dunnage serves a useful purpose in

stowing cargo, but it can also damage cargo. For

example, wet dunnage in the hold of a ship produces

excessive moisture that may damage the cargo.

Oil-stained or dirty dunnage can contaminate

foodstuffs. It is a good practice never to reuse dunnage

until it has been inspected, washed and dried as needed,

and sorted for specific purposes.

There is no definite set of rules governing the use

of dunnage. When using it, you should also use thought

and common sense.

Bagged Material

Many commodities are packaged in burlap or paper

bags. Bagged cargo must be stowed so that it will not

be damaged by moisture. Dunnage should be used to

prevent it from touching stanchions, beams, or other

structures that could cut or tear the bag.

Several ways of stacking bags are shown in figure

14-14. Alternating the bags such as shown in view A

makes a more secure stack. The method in view B

provides more ventilation for material that requires it.

View C shows how dunnage may be used to tie together

the stacks, making them more secure and also providing

increased ventilation. Stacking as shown in view D

permits more bags to be stowed in a given space but

ventilation is greatly reduced.

Cases and Cartons

Generally, cargo consists of an assortment of

wooden and fiberboard boxes and cases constructed in

various sizes and shapes, and which may or may not be

palletized. Careful planning is necessary when you are

stowing such cargo. Skill is also necessary in placing

dunnage. The largest and heaviest cases should be

stowed in the lower holds, and the smaller boxes should

be placed between and around them. This protects the

smaller and lighter cartons and helps to keep the tiers

level. Also less dunnage is required. Figure 14-15

shows another example of using dunnage to floor off,

to distribute the weight of a second level of material

evenly over the first. Using dunnage in this manner is

particularly important when stowing containers of

unequal size and weight.

14-19

|