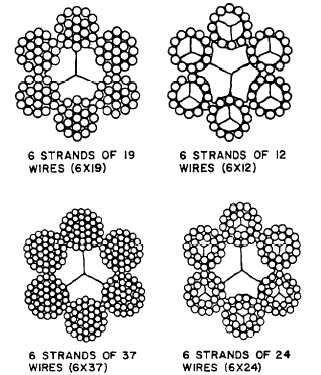

| |

Figure 3-25.–Arrangement of strands in wire rope.

As shown in figure 3-26, wire rope is laid up in

various ways:

RIGHT REGULAR LAY: Wires in the strands are

twisted to the left; strands in the rope are twisted to the

right.

LEFT REGULAR LAY: Wires in the strands are

twisted to the right; strands are twisted to the left.

Figure 3-26.–Lays of wire rope.

RIGHT LANG LAY: Both wires in the strands and

strands in the rope are twisted to the right.

LEFT LANG LAY: Both wires in the strands and

strands in the rope are twisted to the left.

USES OF WIRE ROPE

Chapter 613 of the Naval Ships' Technical Manual

specifies the uses that may be made of wire rope of

various constructions. A few of the more common

constructions and some of their uses follow:

6 X 7: Only the galvanized type is specified. It is not

suitable for general hoisting, but is applicable for

permanent standing rigging.

6 X 19: Size for size, this type of construction is the

strongest of all the wire ropes. When made of

galvanized wire, 6 X 19 is used principally for heavy

hoisting and is particularly useful on derricks and

dredges. Standing rigging, guys, boat slings, and

topping lifts for booms are often made of galvanized

6 X 19 wire rope. Phosphor bronze 6 X 19 rope is used

for lifelines, wheel ropes, radio antennas, antenna

downleads, and so forth, where either noncorrosive or

nonmagnetic properties are desirable.

6 X 37: When made of ungalvanized steel wire, this

construction is flexible, making it suitable for cranes

and similar machinery. It may be used for heavy

hoisting. For instance, hoisting ropes larger than 1 3/4

inches in diameter usually are of this type. When made

of galvanized steel wire, this wire rope may be used for

steering gear, boat crane falls, towing hawsers, bridles,

torpedo slings, and heavy running rigging.

CARE OF WIRE ROPE

Long lengths of wire rope are usually on reels

when received from your supply activity. Never try to

unreel wire rope from a stationary reel. Mount the

reel on a pipe or rod supported by two uprights. This

method allows the reel to turn as the wire rope is

pulled. Unreeling presents no problem, but spooling

the wire rope back onto the reel may give you some

trouble unless you remember that it tends to roll in the

opposite direction from the lay. For example, a

right-laid wire rope tends to roll to the left.

Consequently, start a right-laid wire rope at the left

and work toward the right when spooling over the top

of the reel. When spooling under the reel, start at the

right and work toward the left. Naturally, handle

left-laid wire rope just the opposite.

3-19

|