| |

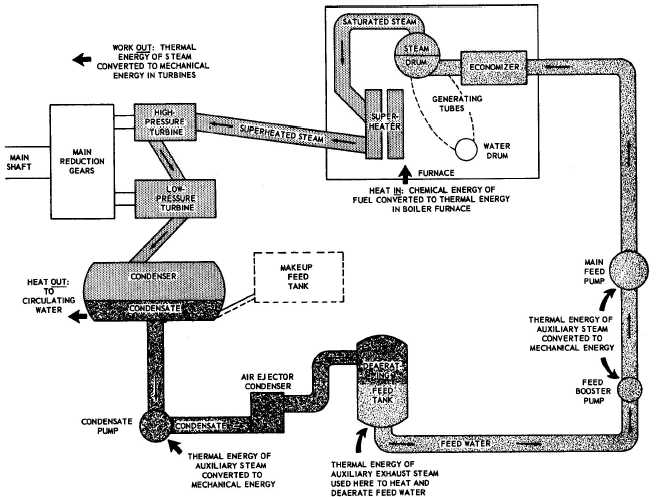

Figure 17-3.—Energy relationships in the basic propulsion cycle of conventional steam-driven ships.

Since superheated steam is dry, it causes less

corrosion of piping and machinery.

For auxiliary purposes, some steam is

desuperheated by passing through the desuperheater

piping located in the steam drum. The superheated

steam is then ready for use to drive the turbine.

Expansion

In the expansion phase the thermal energy of

the steam is converted to mechanical energy in the

turbines. Turbines use nozzles to convert the higher

pressure of the steam into a high velocity. The kinetic

energy of the steam is then transferred to the turbine

blading, creating the mechanical energy of the

turbine rotor. That, in turn, through the reduction

gears, turns the propellers.

Condensation

As the steam leaves, or exhausts through, the

turbine, it is condensed so that the feedwater may be

reused. One boiler can generate 150,000 pounds of

steam per hour. If the feedwater were not recovered,

the system would require an enormously large

evaporator to produce the required feedwater.

As the steam exhausts into the main con-

denser, seawater passes through tubes in the

condenser. The cool seawater cools the steam to the

point of condensation. The condenser operates at a

vacuum, which helps this process and increases the

efficiency of the system.

The condensate pump takes a suction from

the main condenser hot well and delivers the

condensate (condensed steam) into the condensate

piping system and the air ejector condenser. The

17-7

|