| |

excessive wear at this time. If necessary, they are scaled

and cleaned of rust and other foreign matters, checked

for excessive wear or corrosion and, where conditions

warrant, replaced with new ones.

Disassembly of detachable links in the outboard

swivel shot with hairpins requires removal, and

probable destruction, of the lockwire. The availability

of replacement wire of the same type should be

established before removal for inspection of the

detachable link. Replacement hairpins can be fabricated

on board ship from corrosion-resistant steel.

Anchor chain and appendages are carefully

examined for cracks, excessive wear, distortion, or

other defects. Parts that require coating are painted with

anchor chain gloss black paint. Shackles, bolts, locking

pins, and swivels are examined carefully and put in

order. The turnbuckles in chain stoppers require

frequent attention to keep them clean, free from rust,

and well lubricated with a graphite grease.

Chain of sizes by more than 1 1/2-inch wire

diameter is overhauled, wire brushed, and placed in a

good state of preservation as often as required. At least

once every 18 months all anchor chain, regardless of

size, (including all fittings) is examined, overhauled,

and placed in a good state of preservation (5 years for

carriers). To distribute the wear uniformly throughout

the length of the chain, the shots are shifted to a new

position as necessary during this inspection. If, during

overhaul of the chain, significant defects are

discovered, they are brought to the attention of the

Naval Sea Systems Command. If it is not practical to

make immediate replacement, the defective shots are

shifted to the bitter end of the chain. Chapter C6,

Volume 2 of OPNAVINST 5100.19 (series) (NAVOSH

Program Manual for Forces Afloat) contains safety

precautions on ground tackle.

ANCHOR WINDLASS

Windlasses are installed on board ships primarily

for handling and securing the anchor and chain used for

anchoring the ship and for handling anchor chain used

for towing the ship. Most windlasses have capstans or

gypsy heads for handling line in mooring and warping

operations.

Windlasses can be located on the stern of the ship

for stern anchoring, but are usually located in the bow

of the ship for handling bower anchors. Windlasses also

handle bottom-mounted braided fluke anchors (keel

anchors) used on submarines (stern) and some surface

ships (bow).

Landing ships capable of beaching have a separate

anchor winch to handle the stern anchor used for

retracting from the beach.

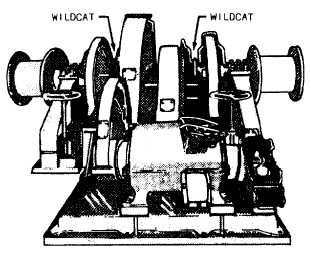

Two general types of windlasses are installed on

naval ships. They are the vertical shaft and the

horizontal shaft types. See figures 4-10 and 4-11. These

two types are subdivided into classes, depending on the

power source. These classes are electrohydraulic drive

and electric drive. The essential parts of a typical

windlass, regardless of its type and class, are the drive

motor, wildcat, locking head, hand brake, capstan or

gypsy head, and control.

Horizontal shaft windlasses are usually made as a

self-contained unit with the windlass and drive motor

mounted on the same bedplate. Vertical shaft

windlasses have their power source located below deck

with only the wildcats and capstans mounted above

deck.

The windlass wildcat is a special type of drum or

sprocket constructed to handle the anchor chain links.

The outer surface has flats (or pockets) which engage

chain links. At each end of the pockets, lugs (known as

whelps) are provided, which contact the end of the flat

link. A central groove in the outer surface

accommodates the vertical links which are not in

contact with the wildcat at any point.

Windlass wildcats have a locking head for

disengaging the wildcat from its power source. The

locking head permits free rotation of the wildcat when

you are “paying out” the chain. Locking heads usually

consist of two sliding block keys that may be shifted to

key together a drive spider and the wildcat. The drive

spider is keyed to the windlass's shaft, while the wildcat

Figure 4-11.–Horizontal shaft anchor windlass.

4-9

|