| |

below before the ship gets outside in heavy weather. If

line must be stowed wet, it should be laid up on gratings

in long fakes so that it may dry as quickly as possible.

It should never be covered over.

SYNTHETIC FIBER LINES

LEARNING OBJECTIVES: Describe the

general usage and care of synthetic line. List

safety precautions for handling synthetic line.

Aramid, nylon, polyester, polypropylene, and

polyethylene, in the descending order of strength are the

synthetic fibers used to make line.

Synthetic fiber line has several advantages over

manila. Size for size, it is 1.7 to nearly 6 times as strong

and lasts 5 times as long. On a strength for strength

basis, a synthetic fiber line of less than half the size of a

manila line is required for the same task. For these

reasons, synthetic fiber is cheaper in the long run, even

if its initial price is more. Because synthetic fiber does

not rot or age as does natural fiber line, its strength is

more stable throughout its life. It is less bulky, more

flexible and, therefore, easier to handle and requires less

stowage space. Other advantages, and a few

disadvantages, are pointed out later in this discussion.

NAVSEA has also approved a new synthetic fiber,

aramid fiber line (Kevlar), for use aboard ship as

mooring and tending lines. aramid rope is lighter, easier

to handle, and smaller than nylon or polyester of

equivalent strength. It also requires less hawser reel

storage space. However, since it stretches only 6

percent at minimum breaking strength, tattle-tale cords

cannot be used to determine the strain on their line, and

the line will respond differently compared to other

synthetic lines, which stretch 30 to 65 percent at

minimum breaking strength. Also, this aramid line does

not fuse and smoke when surged around the bitts. The

line surges smoothly around bitts compared to other

synthetic mooring lines. Aramid line safety precautions

that should be observed will be discussed later.

A coil of synthetic fiber line, unlike natural fiber

line, is not opened by pulling the end up through the eye

of the coil. It should be unreeled in the same manner as

wire rope. (See the section on Wire Rope in this

chapter.) Normally, plain-laid nylon line is right-handed

and should be coiled on capstans and reels in a

clockwise direction. Cable-laid nylon or synthetic line

is left-laid and should be coiled on capstans or reels in

a counterclockwise direction.

Because of the characteristics of synthetic line,

safety precautions more explicit than those for manila

line must be observed. A complete list of precautions is

located in chapter 613 of the Naval Ships’ Technical

Manual (NSTM), but some of the more important

safety precautions to be observed are listed below:

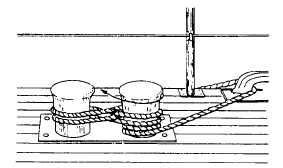

1. Because of the lower coefficient of friction of

synthetic fiber line, exercise extreme care when a line is

being payed out or eased from securing devices (bitts,

cleats). For control in easing out, take two round turns

and no more than two figure-eight bends. Any more than

this will present danger to personnel and difficulty in

handling the line. All lines on capstans and gypsy heads

shall be payed out using power and never by surging.

Figure 3-1 shows the method of securing a mooring line

to the bitts.

2. Since a snap-back action inevitably occurs when

a line parts under tension, never allow personnel to stand

in the direct line of pull of the line when it is being pulled

or when it is under tension. A synthetic line parting under

tension will snap back at near the speed of sound, and

reaction time to clear the area will not be available.

Where possible, position line handlers 90° from the

direction of the tension force (fig. 3-2).

3. Synthetic line has higher breaking strengths than

equal sizes of manila line. Failures of blocks, pad eyes,

shackles, and line couplings can be caused by improper

substitutions. For this reason, personnel should

determine the identification and capacity of all gear and

fittings used with synthetic fiber line to ensure that their

strength exceeds the minimum breaking strength of the

line.

4. Synthetic line has poor knot-holding character-

istics. Some knots that offer good characteristics for

securing manila line, such as the square knot, are not

adequate for belaying or securing synthetic line. The

bowline is one knot known to offer reasonable security

when bending together or securing synthetic line.

Figure 3-1.–Securing lines to bitts.

3-4

|