| |

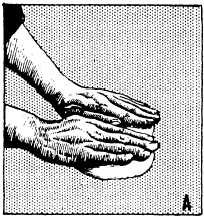

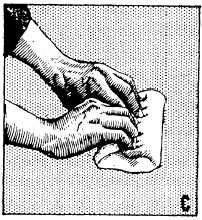

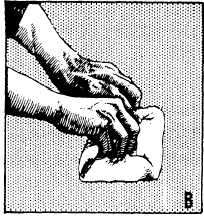

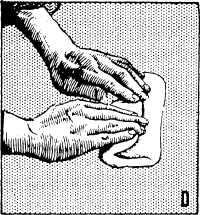

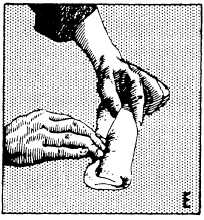

After the dough is molded into a loaf, place it in a

lightly greased pan. Each loaf should be placed so that

the molding seam is on the bottom, and the loaf should

be long enough to reach the ends of the pan. Figure 8-1

provides an example of the molding and shaping of

dough into a loaf.

PAN GREASING.— The primary purpose of

lightly greasing the bread pan is to prevent the bread

from sticking when it is removed. Too much grease on

the pan surface can seriously affect the proofing, baking,

and slicing of the bread.

PAN PROOFING.— After shaping and panning,

loaves should be placed in a properly controlled room

or cabinet called the proof box or proof cabinet for the

final proof or pan proof. Temperature of the cabinet

should be maintained at 90°F to 100°F. During pan

proofing, the action of the yeast is speeded up by the

higher temperature and the gluten becomes more

mellow and elastic.

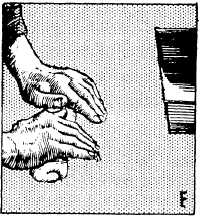

To determine whether the loaf is properly proofed,

touch it lightly with one fingertip and press in slightly.

If the impression made by the tip of the finger remains,

the loaf is proofed. If the imprint does not remain and

fills out when the fingertip is removed, the loaf is still

too compact and should be proofed more. Usually, 50

to 75 minutes is sufficient.

BAKING.— The final stage in bread production is

to place the pans of dough in an oven that is heated to a

temperature sufficient to heat the dough quickly

(temperature specified on AFRS recipes) and to cause

the carbon dioxide of the dough to expand, thereby

greatly increasing the size of the dough. The oven

PRESS GAS

OUT OF DOUGH

PRESS FIRMLY

TO SEAL

FORM RECTANGLE

FOLD RECTANGLE

LENGTHWISE

FOLD AGAIN

Figure 8-1.-Molding and shaping bread dough.

8-6

ROLL TO COMPLETE

SEALING

|