| |

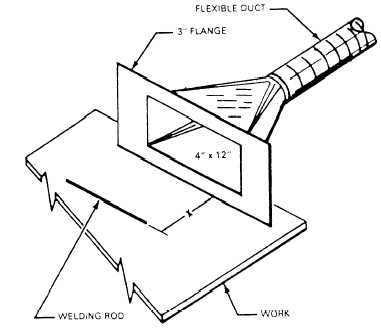

Figure 3-1.—Local exhaust ventilation.

Administrative Control

Administrative control emoploys special operating

procedures to reduce the exposure of personnel to

hazards. Examples include procedures that limit access

to high hazard areas and that provide for adjusted work

schedules such as heat stress safe stay times. Another

example is an operating procedure requiring the use of

semiautomatic equipment that does not require constant

attendance (time separation). Adjusted work schedules

should be used only when personnel maybe repeatedly

exposed to the hazard without adverse effect.

Personal Protective Equipment

The use of personal protective equipment (PPE) is

the least preferred method of hazard control. With this

method, any equipment breakdown, failure, or misuse

immediately exposes the wearer to the hazard. The

effectiveness of the PPE also depends on the conscious

effort of the user to wear it properly. Nevertheless, when

other methods cannot achieve adequate risk reduction,

personal protective devices must be used, either alone

or in conjunction with other protective measures.

HAZARD IDENTIFICATION

Hazard identification occurs through observation

and routine safety program evaluations, surveys, and

formal inspections. The safety officer, safety manager,

safety petty officer, or safety supervisor trains people to

recognize hazards. In chapters 6, 7, and 8, we discuss

the program evaluation and hazard identification

process for shore, afloat, and aviation activities.

HAZARD REPORTING

The earliest possible detection of unsafe or

unhealthful working conditions and the prompt control

of hazards identified as a result of those conditions are

essential. Encourage your subordinates to submit

promptly a report of unsafe or unhealthful conditions.

All personnel should orally report unsafe or

unhealthful working conditions to their immediate

supervisor. That supervisor should promptly evaluate

the situation and take appropriate corrective actions.

Supervisors will contact the Occupational Safety and

Health (OSH) office, safety manager, division safety

petty officer, division officer, or safety officer for

assistance, if needed. The person reporting the hazard

must be kept informed of all actions taken.

After personnel orally report an unsafe or

unhealthful condition, they may expect the supervisor

to investigate the situation. If their supervisor takes no

action to investigate the condition or they are unsatisfied

with the result, personnel may submit a written report.

Ashore, the poster, DD Form 2272, DOD

Occupational Safety and Health Protection Program,

reminds employees that hazard reporting is their

3-7

|