| |

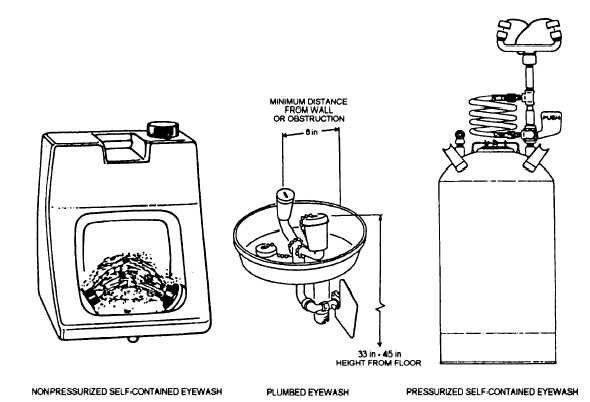

Figure 5-6.—Emergency eyewash stations.

Emergency Eyewash Stations

Emergency eyewash facilities are designed to

provide first aid to personnel who splash corrosive

materials into their eyes. Corrosive materials are espe-

cially hazardous to the eyes because the longer the

materials contact the eyes, the more damage they cause.

If you get a chip of metal in your eye, as long as you

don’t rub your eye, the metal doesn’t cause further

damage. You have time to get to sick bay to have the

eye treated. Chemicals continue to cause damage as long

as they remain in the eyes. Taking the time to go to sick

bay for treatment could result in serious damage to the

eyes. For that reason we need on the spot first aid to wash

the eye to dilute the chemical.

Areas in which corrosive materials are used must

have emergency eyewash facilities. Make sure all such

emergency facilities are easily accessible to personnel

in need of them. Make sure the locations of all units are

unobstructed and are located as close to the hazard as

possible. In no instance should a person have to travel

more than 100 feet or take more than 10 seconds to get

to the eyewash unit. People who work in areas that use

great quantities of corrosives face the risk of splashing

the materials on their body. Those areas must be

equipped with a combination deluge shower and

eyewash station.

Plumbed and self-contained emergency eyewash

equipment (fig. 5-6) flush the eyes using potable water.

The minimum flow rate must be 0.4 gallons per minute

for 15 continuous minutes. Ensure the velocity of the

water will not hurt the user’s eyes.

You must clearly mark each eyewash station with a

safety instruction sign. Post signs in a visible location

close to the eyewash unit. The sign must identify the unit

as an emergency eyewash station.

ASBESTOS CONTROL PROGRAM

For many years, the Navy used asbestos as the

primary insulation (lagging) material in high-

temperature machinery, shipboard boilers, and the

piping of boiler plants at shore facilities. The material

was used as floor tile, as gasket materials, and for other

uses that required fire resistance. We now recognize

airborne asbestos fibers as a major health hazard.

The Navy developed an asbestos exposure control

program to protect and monitor personnel who have

been exposed to asbestos. Aboard ship, many pipes and

boilers still have asbestos insulation. However, the Navy

started a program in the mid- 1970s to use less harmful

materials, such as fibrous glass, for pipe and boiler

insulation.

5-15

|