| |

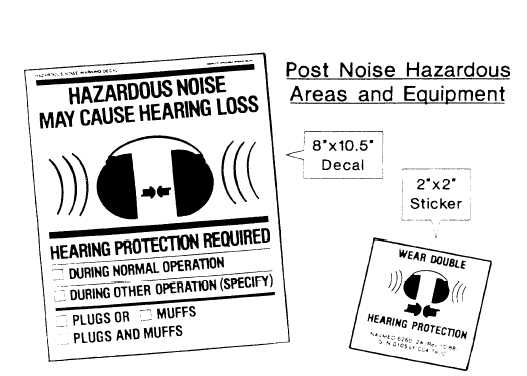

Figure 5-3.—Hazardous noise labels.

The person qualified to take the noise measurements

uses a sound level meter to identify all potentially

hazardous noise areas. The work areas where the sound

level, continuous or intermittent, is routinely greater

than 84 dB(A) or where the peak sound pressure level,

caused by impulse or impact noise, routinely exceeds

140 dB are considered hazardous noise areas. These

areas and equipment are then labeled to warn of the

noise hazard.

Hearing Tests/Audiograms

Hearing tests, or audiograms, are required

monitor the hearing of workers routinely exposed

hazardous noise. Periodic monitoring will allow us

catch a hearing loss before it becomes severe or

to

to

to

to

correct potential problems with hearing-protective

devices. Audiograms test a person’s hearing at a variety

of frequencies in the human speech range. Audiograms

can be conducted at most Navy clinics, aboard tenders,

and aboard air capable surface ships.

Personnel working in hazardous noise areas must be

entered in the Hearing Conservation Program. Military

personnel should have received a reference hearing test

upon entry into naval service. Civilian personnel being

considered for employment in an occupational specialty

or area that involves routine exposure to hazardous noise

should receive a reference audiogram. Navy employees

presently in service who do not have a reference

audiogram filed in their health record will not be

assigned to duty in designated hazardous noise areas

until they receive a reference hearing test. All personnel

should receive a hearing test periodically and before

ending their naval service or civilian service.

Labelling of Hazardous Noise

Areas and Equipment

Make sure you label designated noise-hazardous

areas with the approved 8-inch by 10.5-inch decal (fig.

5-3). Normally, you should apply the proper decals to

the outside of all doors or hatches leading into the

noise-hazardous area. That ensures personnel know

what protection they must wear in that area. Label

equipment, such as hand tools, with the approved

2- by 2-inch hazardous noise sticker, NAVMED

6260/2A (fig. 5-3). This sticker ensures personnel know

whether to wear single or double protection when using

that equipment.

Personal Hearing-Protective Devices

When a hazardous noise area or operation is

identified, we try to control or eliminate that noise

hazard using engineering controls. These controls

include the use of acoustic material, the isolation of

noisy equipment, or the substitution of a less noisy

process. If we cannot reduce the noise to a safe level,

then our only choice is the use of personal protective

5-8

|