| |

Fumes–Very small particles (1 micrometer or

less) formed by the condensation of volatilized solids,

usually metals. Fumes are produced from the welding,

brazing, and cutting of metals.

Gas–A material that under normal conditions of

temperature and pressure tends to occupy the entire

space uniformly. Such material includes hydrogen

sulfide gas from the collection, holding, and transfer

system; acid gas from battery charging; and ammonia

gas from deck stripping. Gases are usually invisible and

sometimes odorless.

Mist and Fog–Finely divided liquid droplets

suspended in air and generated by condensation or

atomization. A fog is a mist of enough concentration to

obscure vision. Mists are produced when you spray

solutions such as paint and spray cleaners.

Smoke–Carbon or soot particles less than 0.1

micrometer in size resulting from the incomplete com-

bustion of carbonaceous materials such as coal or oil.

Vapor (inorganic or organic)–The gaseous state

of a substance that is normally a liquid or solid at room

temperature. Vapors are produced by fuels, paints and

thinners, solvent degreasers, hydraulic fluids, and

dry-cleaning fluids.

Knowing what types of air contaminants these terms

refer to is critical to the proper selection of respirators.

For example, many people believe that paint gives off

fumes. Fumes is a common term used to describe any

smells in the air. However, fumes are actually a

condensed particle of vaporized metal given off during

welding or cutting. If you select a respirator labeled

Dust, Mist and Fumes to protect you from paint

vapors, you will not be protected. Respirator cartridges

are labeled as to the type of protection they provide.

The workplace monitoring plan or the industrial

hygiene survey will pinpoint those areas and processes

that require respirators. Since most ships carry few

exotic chemicals and have limited heavy industrial

work, they don’t need a great variety of respirators or

cartridges. Ashore, extensive industrial work may

require an activity to have a greater selection and variety

of respirators.

Identify Various Types of Respirators

You should be familiar with the three basic types of

respirators:

air-purifying, supplied-air, and

self-contained. An air-purifying respirator removes air

contaminants by filtering, absorbing, adsorbing, or

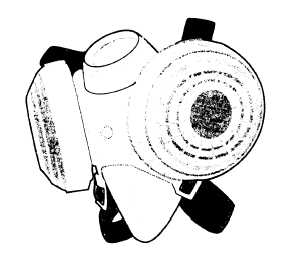

Figure 5-7.—Cartridge-type respirator.

chemical reaction. This respirator may be disposable or

have a disposable prefilter on a cartridge (fig. 5-7).

You can only use the air-purifying respirator when

the adequate oxygen (19.5 to 23.5 percent by volume)

is available and the contaminant level is not immediately

dangerous to life or health (IDLH). We classify

air-purifying respirators as follows:

Particulate-removing–These respirators have

filters that remove dusts, mists, fumes, and

smokes by physically trapping the material on the

filter surface.

Gas- and vapor-removing–These respirators

have cartridges that absorb or chemically bind

vapor or gas within the cartridge.

Combination particulate and gas- and vapor-

removing–These respirators are a combination of

the preceding two types of respirators. They are

required when you have a combination of

materials such as a particle (mist) and a vapor.

Since these air-purifying respirators are negative-

pressure respirators, they can only be used with air

contaminants that have good warning properties, such

as odor or taste. Warning properties indicate when the

mask is leaking or the cartridge is used up.

The supplied-air respirator provides breathing air

independent of the environment. You must wear this

type of respirator when the following conditions exist:

1. Contaminant does not have enough odor, taste,

or irritating warning properties

5-19

|