| |

wheel conveyor. The second is the portable

power-driven belt conveyor.

The gravity-type roller or wheel conveyor can

be installed with one end lower than the other to

take advantage of gravity or it can be installed

level and the load pushed along manually. Several

sections can be put together and developed into

a continuous system for movement of material on

the ship during underway replenishment or

vertical replenishment. The conveyor can also be

used on piers, in storerooms, or wherever a steady

flow of supplies is desired.

The power-driven belt conveyor consists of an

endless belt mounted on a frame and driven by

a pulley connected to a drive motor. The belt

travels over a series of rollers or a sliding bed. The

belt conveyor can be used to transport materials

over a fixed path of travel up inclines of as much

as 25 degrees.

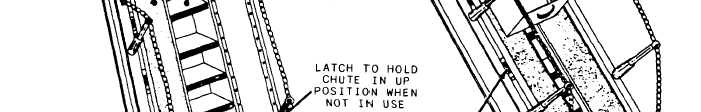

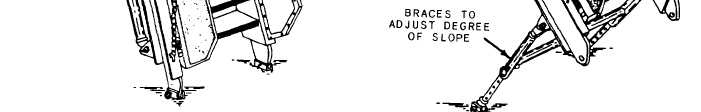

Ladder Chute

The ladder chute shown in figure 4-8 provides

a rapid means of conveying packages downward.

The principal application is aboard ship where a

need exists to strike down stores.

MANUAL HANDLING

As we mentioned earlier, a great deal of

material handling is done manually. It is

important that you understand how to lift

correctly because many times personnel in

working parties and other material handlers do

not think about how they lift or handle materials.

The results of improper handling of materials may

be a painful hernia, a strained or pulled muscle,

or a disk lesion. The correct method of lifting

objects is shown in figure 4-9. You should observe

the following rules and precautions for lifting:

1. Do NOT lift an object if it is too heavy or

too bulky for good balance. Get help or use

mechanical aids such as a dolly or hand truck.

2. Keep the load close to the center of your

body. The farther the load is from the small of

your back, the greater the strain. That is the

reason a heavy compact load is easier to lift than

a bulky lighter load—you just cannot get the

Figure 4-8.—Stores strike-down chute.

4-10

|