| |

The advantages to using material-handling

equipment are quite noteworthy. It speeds up the

availability of material and reduces the amount

of manpower required. It accomplishes this by

large single movements of stock, which simplifies

the stowing and shipping of material with the use

of less people. Handling materials in this fashion

also reduces the risk of damage to materials and

reduces personnel fatigue and injuries.

Pallets

A pallet is a low, portable platform built of

wood, metal, or fiberboard, built to specified

dimensions, on which supplies are loaded, trans-

ported, or stored in units. Flat pallets are either

single-faced or double-faced. Single-faced pallets

have one platform with stringers underneath on

which the weight of the load rests. Double-faced

pallets have two platforms separated by stringers.

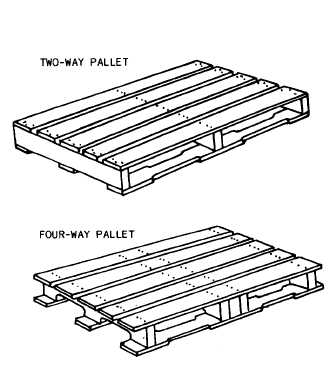

Pallets may afford two-way or four-way entry.

The two-way entry pallet is built so the forks of

a forklift truck may be inserted from either the

front or rear of the pallet. The four-way pallet

is built so the forks of a forklift truck may be

inserted from any of the four sides. Both of these

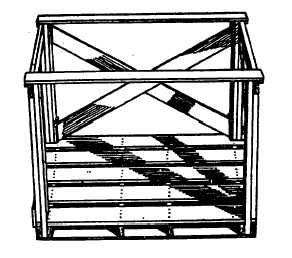

pallets are shown in figure 4-2. The box pallet

shown in figure 4-3 is used primarily for handling

small lot items or easily crushed material.

Figure 4-3.—Box pallet.

When loading a pallet, three things must be

considered: (1) maximum load, (2) stability, and

(3) proper pallet size. Make sure the pallet will

pass through all doors, aisles, and hatches likely

to be encountered. The stability of the material

on the pallet must be considered and a decision

made as to the type of pallet to use, platform or

box pallet.

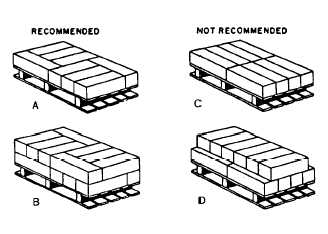

Figure 4-4 shows the recommended and not

recommended ways to load material on a pallet.

Since the size of the boxes being loaded will

determine their arrangement on the pallet, a

standard loading pattern is not always appro-

priate. However, in the illustration you can see

that the material not only fits the pallet (in

recommended A and B stacking), but they are

arranged to provide stability against slipping and

sliding. Boxes of materials are not always the same

Figure 4-2.—Two-way and four-way pallets.

Figure 4-4.—Loading pallets (views A, B, C, and D).

4-7

|