| |

from the extractor. Iron flatwork immediately

while it is at the proper stage of dampness, or

cover it with plastic or other material to retain a

proper amount of moisture. Feed flatwork into

the ironer WRONG SIDE UP, so that the smooth

or “right” side comes into contact with the

cylinder. This gives a smooth finish to the outside

of the flatwork. Fold the smooth side out as the

work comes from the machine.

Large Items

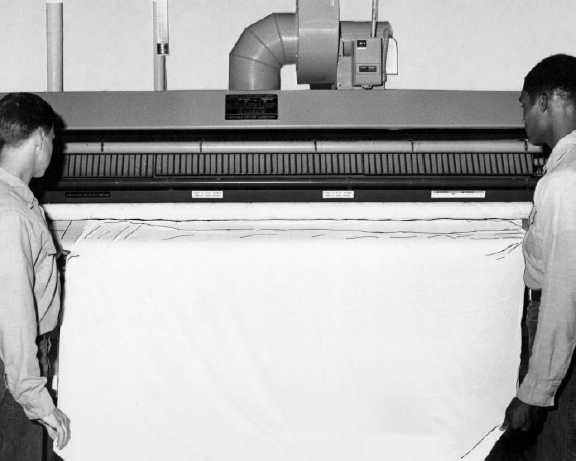

Two persons should feed large items as

shown in figure 5-31. To start the piece through

the ironer, each person grasps a top corner with

the hand nearest the ironer, stretching the

forward edge between them so that it enters the

machine straight and smooth. Each person uses

the other hand to straighten the front edge as it

enters the ironer. After the feed roll ribbons pick

up the spread, they use both hands to hold the

spread firm and straight as it passes through the

ironer. As the spread comes out, the personnel

take it by the edges again and fold it.

Small Items

When you feed small articles into the

flatwork ironer, use the entire length of the

cylinder, If you continually feed small items into

the ironer at one or two spots, the padding on the

pressure rolls wears more at these points and

your work comes out unsatisfactory. The only

way to correct this difficulty is to repad the rolls.

CARE AND MAINTENANCE

Maintenance of the flatwork ironer is the

responsibility of engineering personnel. ONLY

trained maintenance personnel should do any

work on the ironer. Instructions for changing

43.79

Figure 5-31.-Laundry personnel using the flatwork ironer.

5-41

|