| |

cylinder and returns it to the front. Steam to heat

the cylinder is provided by the ship’s steam line,

and the motor is electrically driven.

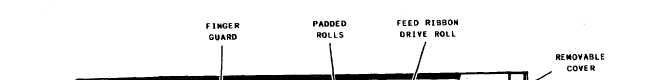

The ironer parts that you are mainly concerned

with are shown in figure 5-30. The one part not

shown that is very important is the emergency stop

button located in the right-hand rear of the

machine. We will briefly describe the main parts

so you can get a broad understanding of the

flatwork ironer.

The return ribbons hold flatwork in

contact with the heated cylinder until

discharge.

The delivery table catches all discharged

material.

The finger guard prevents the hands

of the operator from getting near the

padded pressure rolls.

The padded rolls smooth and flatten fabric

to the heated cylinder.

The feed ribbons feed flatwork.

The feed ribbon drive roll turns the feed

ribbons.

The speed control lever controls the

speed in which flatwork is passed through

the ironer.

The foot pedal engages the compression

roll.

SAFETY PRECAUTIONS

Before discussing operation of the flatwork

ironer, we need to discuss safety precautions that

apply to this equipment. Do not try to remove

jammed linen or material while the machine is

running. Serious injury to the operator or damage

to the ironer can occur if you attempt to reposition

or unjam linen or service the ironer while it is

running. If something is jammed, shut the ironer

off at the power source before trying to remove

it. If the ironer has compression roll levers, learn

how these levers work and always use them to

Figure 5-30.—Flatwork ironer basic parts.

5-39

|