| |

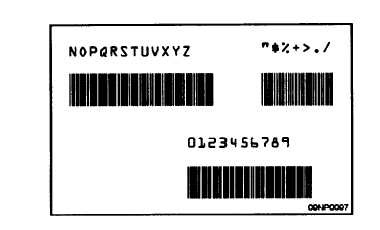

Figure 11-3.—Example of a 3-of-9 bar code arrangements.

spaces when a given number of bars are read and vice

versa. If the scanner reads an incorrect number of bars

for the number of spaces read (or vice versa) or if the

read data element is not begun and ended with a

start/stop mark, then a “no-read” condition exists. With

a good quality marking, the first read rate is near 100%

and the character substitution (misread) rate is less than

1 error per 6,000,000 characters read. However, less

than desired printing quality or label condition will

degrade the first read rate, while the character

substitution rate will be affected only slightly.

Our computers today depend on us to manually

input data into a device that converts information into a

machine acceptable form-punched cads, magnetic

tapes, or electric signals from a terminal. As we have

all experienced, manual input is prone to error and speed

is limited to a person’s manual dexterity. Bar code data

can be scanned and converted accurately into computer

usable form without manual keying.

BAR CODE APPLICATIONS

From the moment material first enters the supply

system until it is issued, these bar codes can be scanned

to provide key data for a variety of applications such as

Location Survey —Presently, the Uniform

Automatic Data Processing System-Stock Point system

(UADPS-SP) produces a tape with the location to be

surveyed and each stock number that is supposed to be

in that location. his tape is converted to cards. The

warehouseman uses these cads to go to the location,

check material in the bin, and handwrite corrections on

the cards. The cads are returned for keypunching. The

punched cards are then converted to tape which is used

to update the Master Stock Item Record (MSIR).

With the locations labeled with their number in bar

code and a portable scanner, cards are eliminated The

scanner would be loaded with images from the

UADPS-SP tape. The warehouseman is prompted by

the scanner to go to a particular location. The

warehouseman confirms he is at the right place by

scanning the location bar code label. The scanner then

displays what stock number should be in the bin, its

condition code, shelf-life, etc. The warehouseman

validates this information, makes corrections on the

scanner’s keyboard, and inputs any stock number in the

location which is not shown on the scanner.

These

scanners have up to 60,000 character memories so the

warehouseman can survey a number of locations.

When the warehouseman is done, the scanner’s

information is converted into a tape which updates the

MSIR.

Physical Inventory—To conduct a physical

inventory, portable scanners are used in a way similar

to a location survey. The locations and items to be

inventoried are loaded into the scanner, the items

inventoried, and the scanner’s data passed to the main

computer. As more and more incoming material is bar

coded, the warehouseman will be able to scan the bar

code label with the stock number on the item’s box

rather than write it down or key it into a scanner.

Material Receiving—Scanning light pens attached

to a video terminal will be used to obtain the stock

number and contract number off the incoming outer

container. With these two pieces of data, the computer

system will retrieve other pertinent information about a

receipt from the Due-In File. The receiving personnel

can input quantity received and be told where this item

should be stored. The capability to print a barcode label

for those items received without labels will also

available.

AUTOMATIC DATA PROCESSING

One of the most significant characteristics

be

o f

automatic data processing (ADP) is that a complete

series of operations can be planned The machine can

then be directed to carry them out without further

human intervention.

An ADP installation which includes several

individual equipments is usually called a SYSTEM.

The system must be able to accomplish four

fundamental functions.

Accept data

Accept instructions

11-3

|