| |

from which specially designed hooks are suspended at

front and rear (figure 13-16C). The attachment is

lowered over the drums until the hooks drop into

position over the drum rims. This attdachment handles

two filled drums at one time. The third type of

attachment, which is vertically operated, handles one

filled drum at a time. (See figure 1346 D.) The fourth

type of drum-handling attachment operates on the

principle of vacuum. This attachment is not in wide use.

This is because of the expense involved in the

installation of this attachment and the fact that once

installed the use of the forklift truck is restricted to drum

handling only.

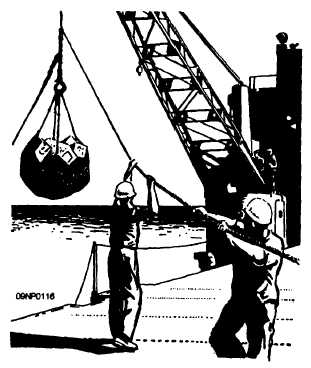

CARGO NET SLING

The cargo net sling (figure 13-1 7) is made of nylon

straps cargo together in a crisscross pattern to form a 12

foot square or 14 foot square net. The four comers of

the net have steel rings sewn in for the pickup hoist

hooks or lines used to form an apex. In this type of sling

no bars are used as supports. The idea being that the net

closes about the material being lifted.

Cargo net slings are generally used aboard Combat

Logistics Force (CLF) ships for underway

replenishment (UNREP) operations support. Pallets of

cargo can be placed in the net and transferred with a

minimum of loss. Some ships use cargo net slings for

handling miscellaneous cargo that is placed directly into

the net as shown in figure 13-17.

ROLLERS, CONVEYORS, AND CHUTES

Conditions may be such that rollers conveyors, or

chutes are more effective than mobile equipment or may

supplement mobile equipment when a deficiency of

mobile equipment exists.

Rollers

Hardwood rollers or pipes may be placed under

heavy boxes or skids so that they maybe moved about

in a storeroom or vehicle. Two or more rollers are used,

depending on the weight of the box. The end of the box

toward the direction in which the box is to be moved is

raised by a hoist, lever, or other lifting device, and a

roller is placed under it. The box is then pushed forward

as more rollers are placed in front of it. As the box

passes off a roller, the roller is picked up and placed in

front of the box.

Figure 13-17.—Cargo net sling.

Conveyors

A conveyor is a device for moving supplies in a

fixed line of travel. Two basic types of conveyors have

been adopted as standard for the military departments,

the powerdriven belt conveyor and the gravity-type

roller or wheel conveyor.

The power-driven belt conveyor consists of an

endless belt mounted on a frame and driven by a pulley

connected to a drive motor. The belt travels over a

series of rollers or a sliding bed. The belt conveyor can

be used to transport materials over a fixed path of travel

up inclines of as much as 25 degrees.

The roller conveyor can be installed with one end

lower than the other to take advantage of gravity. It can

also be installed level and the load pushed along

manually. Several sections can be put together and

developed into a continuous system for movement of

material. The conveyor can be used on piers, in

storerooms, or wherever a steady flow of supplies is

desired. A drop of one-half inch per foot is usually

required to keep an object in motion on the rollers.

Figure 13-18 shows their use in clearing the landing

area of the receiving ship during underway

replenishment. Folding stands maybe used when it is

necessary to clear obstructions on the deck or to pass

through doors. Accesories for horizontal conveyors

include turntables and curved sections.

13-8

|