| |

chain may be used depending on the weight of material

to be lifted.

Slings have rigid horizontal supports at the base.

Usually made of steel bars or pipes that must be of

sufficient strength to distribute the load across the entire

length.

Some slings have movable spreader bars at the top

to prevent the load from being crushed when lifted.

PALLETS

A pallet is a wooden, steel, or aluminum platform

on which supplies are loaded, transported, or stored in

units. Use of pallets permits handling the material with

forklift trucks, cranes, and other transporting

equipment.

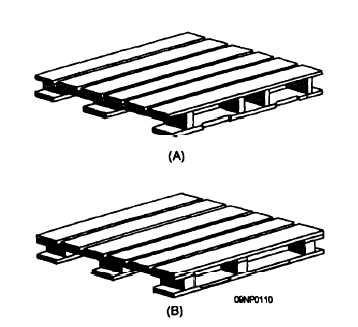

The standard pallet is a 40- by 48-inch platform that

accommodates most packages and stores in

warehouses. It is regarded as the general-purpose

pallet. General-purpose pallets maybe either the flat

type or box type. Flat Pallets may be single-faced or

double-faced. Single-faced pallets (figure 13-11) have

one platform nailed or bolted to stringers, usually made

of 2- by 4-inch material. A double-faced pallet (figure

13-10) has platforms on the top and the bottom of the

stringers and is excellent for stevedoring and

transit-shed operations.

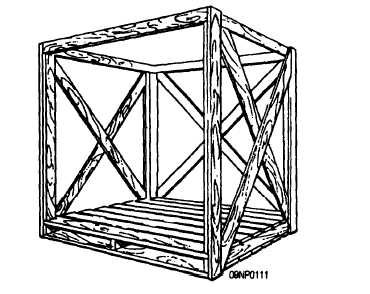

The box-type pallet, illustrated in figure 13-12, is

used for handling small-lot items or easily crushed

Figure 13-12.—Box pallet.

cargo. When discharging items from a ship to a transit

shed, loading directly into a box pallet saves

considerable time and labor.

Nestable sheet metal pallets are convenient for three

reasons (1) the maintenance cost is low, (2) they save

storage space, and (3) you have no problem keeping

them sanitary. Figure 13-13 shows a few single-faced

pallets stowed alongside a stack of sheet-metal pallets.

As you can see, the saving in storage space is

tremendous.

Lightweight aluminum pallets also are used, but are

expensive and difficult to repair.

In addition to the standard pallet there is a 48- by

72-inch stevedoring pallet, which is used primarily for

transporting and storing drummed products and for

stevedoring purposes.

Pallet construction and

illustrations on the stevedore pallet can be found in

NAVSUP P-284-1.

Loading Pallets

When a pallet is loaded, three things must be

Figure 13-11.—Pallet, x 48-inches, four-way entry:

Partial stringers (B) Post canstruction.

(A)

considered: (1) maximum load, (2) stability, and (3)

proper pallet size. The pallet must pass through all

doors, aisles, and hatches likely to be encountered. The

stability of the material on the pallet must be considered

and a decision made as to the type of pallet to use.

Figure 13-14 shows the recommended way to load

material on a pallet. The size of the boxes being loaded

will determine their arrangement on the pallet. A

standard loading pattern is not always appropriate.

13-5

|