| |

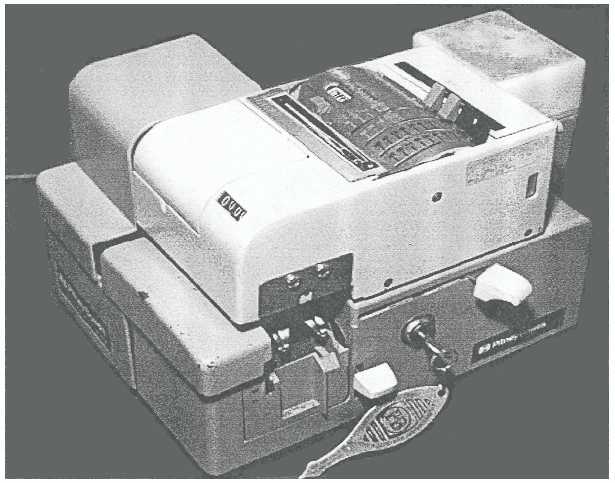

Part 8: COUNTER WINDOW. This counter advances

once each time you produce a meter tape. This counter

cannot be reset manually.

Part 9:

METER MANUFACTURER.

The

manufacturer’s logo and name are engraved on the

meter.

Part 10: SERIAL NUMBER. The meter head serial

number is also engraved on the meter and is usually

located above the high denomination button.

Each

meter head has its own unique number. Each time a

meter tape is produced, this serial number is printed on

the tape indicating which meter produced it.

The following are parts of the meter base:

Part 1:

TAPE AND INKER COMPARTMENT

COVER. This cover protects the ink rollers and meter

tape from being damaged. By grasping the upper-left

portion of the machine and pulling it out and to the left,

both the tape and inker compartments are exposed.

Part 2: INKER. The inker assembly consists of two

absorbent rollers that are mounted on a metal bracket.

The larger of these rollers is saturated when new, with

enough ink to produce approximately 15,000 tape

stamps.

Part 3: WATER CONTAINER. This container is used

to moisten tapes when the deflector switch is in the

“WET” position.

Part 4: CUSTOMER’S LOCK. This is a cylinder lock

used for locking the meter on the machine and to lock

the machine against operation. To place the machine on

the “lock” position, shift the operating lever (Part 5) to

the center position between OPERATE and REMOVE,

then turn the key clockwise one-half turn and remove

the key.

Part 5: OPERATING LEVER. This lever can be set at

one of three positions, REMOVE (forward position),

LOCK (center position) or OPERATE (rear position).

The operating lever engages the meter to the machine

when it is moved to the extreme rear position. This lever

must be moved fully forward when you wish to install or

remove the meter or when you wish to engage the meter

when it has been secured.

8-17

PCf0808

Figure 8-8. An example of a meter head engaged to the meter base.

|