them sanitary. Lightweight aluminum pallets also are

used, but are expensive and difficult to repair.

Loading Pallets

When a pallet is loaded, three things must be

considered: (1) maximum load, (2) stability, and (3)

A

proper pallet size. The pallet must pass through all

doors, aisles, and hatches likely to be encountered. The

stability of the material on the pallet must be

considered and a decision made as to the type of pallet

to use.

Figure 7-15 shows the recommended way to load

material on a pallet. The size of the boxes being loaded

will determine their arrangement on the pallet. A

standard loading pattern is not always appropriate.

However, in the illustration you can see that the

B

SKf07013

material not only fits the pallet, as recommended in A

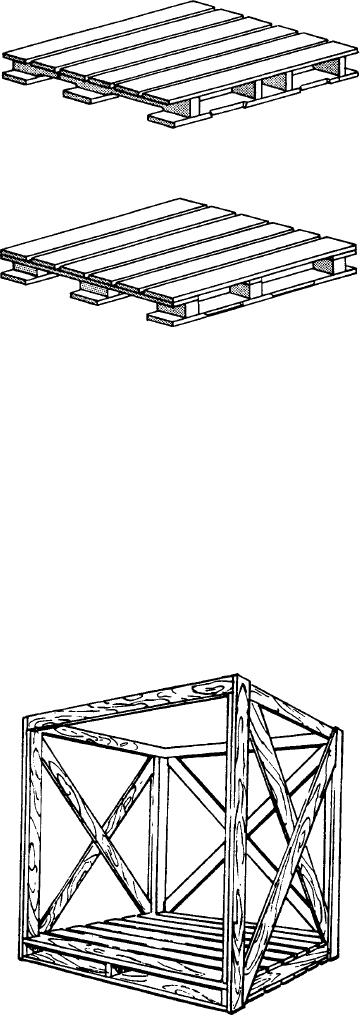

Figure 7-13.--Pallet, 40 x 48 inches, four-way entry: (View A)

and B stacking, but is arranged so as to provide stability

Partial stringers (View B) post construction.

against slipping or sliding.

Boxes of materials are not always the same size.

bottom of the stringers and is excellent for stevedoring

When this is true, place the highest and strongest cases

and transit-shed operations.

at each end of the pallet and the smaller and more fragile

cases in the center. This arrangement provides a

The box-type pallet, illustrated in figure 7-14, is

stronger surface for a second tier of eases on the pallet

used for handling small-lot items or easily crushed

and also makes it possible to place a second loaded

cargo. When discharging items from a ship to a transit

pallet on top for storage.

s h e d , l o a d i n g d i r e c t l y i n t o a b o x p a l l e t s ave s

considerable time and labor.

When you palletize round items, such as gas

cylinders, use specially constructed notched spacers or

Sheet metal pallets are convenient for three

collars as shown in figure 7-16.

reasons (1) the maintenance cost is low, (2) they save

storage space, and (3) you have no problem keeping

Palletized material that must be moved several

times should be strapped. Metal or nylon strapping may

be used; the number of straps required for a palletized

unit depends upon the kind of handling it is to receive.

The tool used to tighten the strapping is capable of

exerting a great amount of force. Therefore you must be

careful not to crush the material. Metal or folded

cardboard corners may be placed under the strapping to

distribute the force over a wider area and help prevent

damage to the cartons or their contents.

DRUM-HANDLING EQUIPMENT

The drum-handling sling is a device for picking up

drums or barrels. It was designed for shipboard loading,

but may be used with a crane for any drum or barrel

handling operation. The sling may be of the chain type

(figure 7-17, View A), which is a series of chain loops

and sliding hooks. It may also be of the frame type,

SKf07014

Figure 7-14.--Box pallet.

7-6