| |

Operating over sheaves and drums with

improperly fitted groves or broken flanges

Jumping off sheaves

Subjecting to moisture or acid fumes

Attaching fittings improperly

Permitting to untwist

Subjecting to excessive heat

Promoting internal wear by allowing grit to

penetrate between the strands

Subjecting to severe or continuing overloads

Kinking

SEIZING WIRE ROPE

Seizing is the process of securing one rope to

another, two or more parts of the same rope to itself, or

fittings of any kind to a rope by binding with small stuff

or with annealed iron wire.

In the manufacture of wire rope, great care is taken

to lay each wire in the strand and each strand in the rope

under uniform tension. If the ends of the rope are not

secured properly, the original balance of tension will be

disturbed and maximum service will not be obtained

because some strands will carry a greater portion of the

load than others. Before cutting steel wire rope, you

must apply proper seizing on both sides of the place

where the cut is to be made. For preformed wire rope,

one seizing on each side is normally enough. For wire

ropes that are not preformed, a minimum of two seiz-

ings is required, placed six rope diameters apart.

Always apply seizing in the opposite direction from the

lay of the rope. This prevents loosening when the wire-

rope shrinks as a result of loading. Remember that the

length of the seizings must never be less than the

diameter of the wire rope being seized.

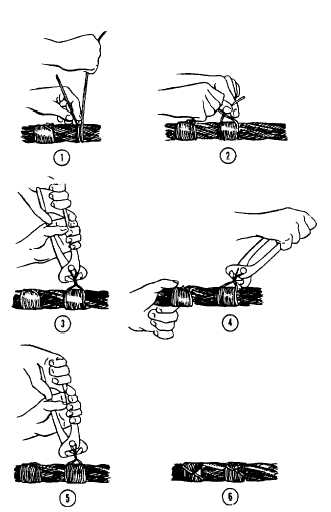

To make a temporary wire-rope seizing, wind on

the seizing wire uniformly, using strong tension on the

wire. After taking the required number of turns as

shown in step 1 in figure 3-31, twist the ends of the

wires counterclockwise as shown in step 2. Grasp the

ends with end-cutting nippers and twist up slack as

shown in step 3. Do not try to tighten the seizing by

twisting. Draw up on the seizing as shown in step 4.

Twist up slack Repeat steps 4 and 5 if needed. Cut the

ends and pound them down on the rope as shown in

step 6. If the seizing is to be permanent, or the rope is

1 5/8 inches or more in diameter, use a serving bar or

Figure 3-31.–Putting seizing on wire rope.

iron to increase tension on the seizing wire when putting

on the turns.

You must use the proper size and grade of wire for

seizing. Table 3-3 lists the proper sizes of seizing wire

for use with a range of wire-rope diameters.

Table 3-3.–Seizing for Wire Rope

Rope Diameter

Annealed Iron Seizing

(inches)

Wire Diameter (inches)

1/2 and smaller

0.035

9/16 to 7/8

.063

1 to 1 1/2

0.92

1 5/8 to 2 1/8

.120

2 1/4 and larger

.135

3-23

|