| |

use on truck and reefer floors. The 24 wheels in the

central portion (figure 13-27C) are placed slightly lower

than the wheels at the ends. The wheels at the ends are

held in position by springs, which allow them to move

on their axles as the load is guided to its destination. The

difference in height of the center and end wheels permits

a certain amount of recking motion which aids in

movement and guidance of the pallet load. That is, the

tilting effect allows the dolly to turn, and the center

wheels (on offset axles) prevent loading of wheels in

slatted floors.

MATERIALS HANDLING ABOARD

SHIP

The use of materials-handling equipment aboard

ship is dependent upon several factors: type of ship, its

physical characteristics, and quantity of material to be

moved.

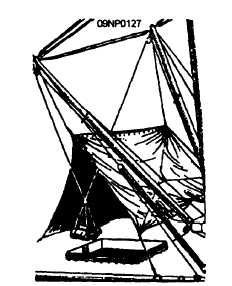

On cargo ships, the primary method of moving

material is by cargo booms. These booms may be

rigged to provide the required lift capability and to reach

the required work area. The most common rig is the

“yard and stay” which uses two booms and two winches

with the two wire ropes (whips) corrected to a single

cargo hook. In loading from or to a pier, one boom is

positioned over the hold and the other rigged out so that

the head of the boom is over the pier. The load may then

be picked up on one boom, transferred to the second by

taking in on the second whip while paying out the first

whip, and lowered from the second boom.

Figure 13-28 shows a yard and stay rig with a

suspended load. Also shown is one type of hatch tent.

Figure 13-28.-Cargo booms with Seattle hatch tent.

The Seattle hatch tent may be used to protect personnel

and cargo in the hold during inclement weather. A hatch

tent provides protection not only from rain or snow but

also from the sun during very hot weather.

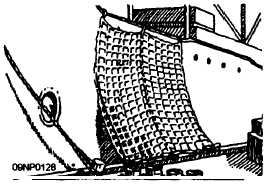

A save-all is a device used to prevent the loss of

cargo overboard during loading or discharging

operations. The most common type of save-all,

(shown in figure 13-29) is a net (rope or nylon)

approximately 15 by 20 feet or larger. Wire rope nets

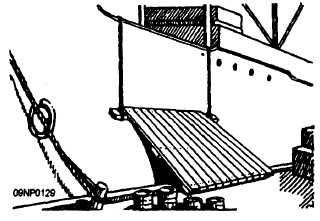

and wooden platforms (figure 13-30) may also serve

as save-alls. There should be a save-all rigged to each

working hatch, and also beneath each brow, skid, or

conveyor if the ship is loading or discharging through

sideports.

You can rig a save-all by lashing one side of a net

even with the bulwark. Then by securing it to cleats on

the deck or bulwark, and securing the bottom of the net

to the stringer on the pier. Leave enough slack in the

save-all to allow for the rise and fall of the tide.

A save-all may be improvised by lashing together

several cargo nets.

When working light cargo, a

tarpaulin may serve as a suitable substitute.

Figure 13-29.—Rope save-all.

Figure 13-30.— Wooden save-all.

13-13

|