| |

DD cannot accept requisitions directly or issue

stock without the prior authorization of the DSC.

The principal DDs are located in Mechanicsburg,

Pennsylvania; Memphis, Tennessee; Ogden,

Utah; and Tracy, California.

Specialized Support Depots

Because of the large number of afloat

customers, the DLA has established two SSDs to

provide direct support to the Navy. The two SSDs

are the Navy supply centers at Norfolk and

Oakland. The SSDs, unlike the DDs, have the

authority to receive requisitions directly and to

make issues locally. The inventory held at each

depot is, however, owned and managed centrally

by the cognizant DSC.

NAVY SUPPLY SYSTEM

As was mentioned at the beginning of the

chapter, the Navy supply system is integrated with

the Defense Logistics Agency system. The mis-

sion, organization, and functions of the com-

ponents of the Navy system are described below.

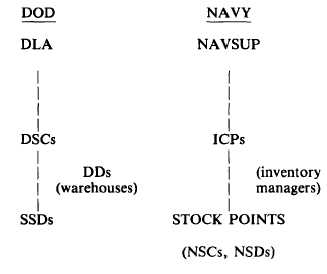

Like the DLA system, there are inventory

managers (the inventory control points), a

distribution system (NSCs, NSDs), and a central

headquarters (NAVSUP). The following diagram

is a comparison of the two systems:

NAVAL SUPPLY SYSTEMS

COMMAND

The Naval Supply Systems Command (NAV-

SUP) supervises the provisioning, cataloging,

inventory management, distribution, materials

handling, traffic management, transportation,

packaging, preservation, receipt, storage, issue,

and disposal of Navy supplies and material, ex-

cept for those items specifically assigned to other

systems commands or offices. Although NAV-

SUP relies heavily on the other systems commands

for technical advice concerning equipment and

material requirements, it also furnishes supply

management methods and guidance to commands

and offices that request management assistance

in supply functions.

NAVSUP is also responsible for the develop-

ment and supervision of the Navy supply system.

It must combine all supply and distribution func-

tions into one system so that the system can meet

the objective of responsive and efficient material

support to the operating forces. This is not a

simple task. The Navy supply system must be

responsive to all levels of command and must

operate at all levels. It is not enough to develop

only those capabilities that will enable a supply

system to meet the needs of one ship, one task

force, or one fleet. The Navy supply system must

be able to respond to all the needs of the operating

forces and of their related support activities.

As you read the following sections, you should

recognize how many supply functions are inter-

related so that the Navy supply system can sup-

port your ship or any other component of the

operating forces. You should also determine how

your supply department, afloat or ashore, func-

tions in much the same way in meeting the needs

of a ship or a station. The basic elements of supply

support, for one ship or for the entire Navy,

involve the determination of requirements, pro-

curement, and distribution.

Determination of Requirements

Determining requirements for material should

not be new to you as you have probably already

had some experience in this area aboard your ship.

In performing this job, you have had two excellent

tools to work with—the Coordinated Shipboard

Allowance List (COSAL) and the usage data from

your stock record cards. The COSAL is discussed

later in this rate training manual and in Military

Requirements for Petty Officer Third Class

through Chief Petty Officer. The Navy supply

system uses the COSAL and stock record cards

for determining the requirements for replenish-

ment materials. However, not all material comes

under the heading of replenishment. When new

material, such as the repair parts requirement

for a newly developed item of equipment, is

2-3

|