| |

If wire rope is being run off one reel to a winch drum

or another reel, run it from top to top or from bottom to

bottom, as shown in figure 3-27.

Make up short lengths of wire rope in coils and stop

off tightly for stowage. When uncoiling wire rope, stand

the coil on edge and roll along the deck, uncoiling as you

go, as in figure 3-28.

Whenever possible, drums, sheaves, and blocks

used with wire rope should be placed so as to avoid

reverse or S-shaped bends. Reverse bends cause an

unnecessary amount of shifting of the individual wire

strands, increasing wear and fatigue. Where a reverse

bend is needed, the blocks and drums effecting the

reversal should be of larger diameter than ordinarily

used and should be spaced as far apart as possible.

If a wire rope becomes kinked, never try to pull it

out by putting a strain on either part. As soon as a kink

is noticed, uncross the ends by pushing them apart. See

step 2 in figure 3-29. Performing these steps reverses

the process that started the kink. Now turn the bent

portion over and place it on your knee or some firm

object and push downward until the kink straightens out

somewhat. Then lay it on a flat surface and pound it

smooth with a wooden mallet.

If a heavy strain is put on a wire rope with a kink in

it, the rope no longer can be trusted. Cut out the kinked

part and splice the ends together.

Frequently, abrasion or reverse or sharp bends cause

individual wires to break and bend back. These broken

wires are known as fishhooks.

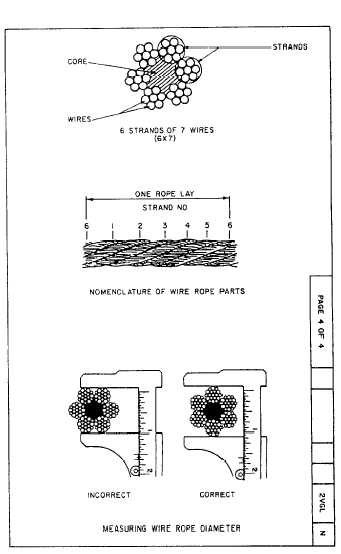

Wire rope should be inspected frequently, checking

for fishhooks, kinks, and worn and corroded spots.

Worn spots show up as shiny flattened surfaces. To

determine the wear, you must know (1) the original

diameter of the wire rope, (2) the present diameter of

the wire rope at the worn place, and (3) the diameter of

a single wire in one of the strands of the wire rope. The

original diameter of the rope is shown in the ship's

allowance list or in the first lieutenant's records. The

actual diameter of the rope is found by measuring it with

a micrometer or vernier caliper, as shown in figure 3-30.

One or more of the following conditions is

sufficient reason for questioning the rope's safety and

considering replacement:

1. The normal rope diameter is reduced by more

than the amount shown in table 3-2 for the applicable

size rope. See figure 3-30 for the correct method of

measuring diameter.

2. Six broken wires in one rope lay length, or three

broken wires in one strand lay length. See figure 3-30

for definition of a lay length.

Figure 3-30.–Measuring wire-rope diameter.

Table 3-2.–Wire-Rope Allowable Diameter Reduction

Maximum Allowable

Nominal Diameter

Rope Diameter (inches)

Reduction (inches)

5/16 and smaller

1/64

3/8 to 1/2

1/32

9/16 to 3/4

3/64

7/8 to 1 1/8

1/16

1 1/4 to 1 1/2

3/32

19/16 to 2

1/8

2 1/8 to 2 1/2

5/32

3-21

|