| |

A complete set of working tools and repair

equipment must be maintained in a location that can be

readily accessed by transfer station personnel. Tools

and equipment should be inventoried and checked for

proper operation before each replenishment. Each

transfer station should maintain, as a part of station

equipment, a listing of all items (tools, spares, and so

forth) that may be required to repair the station, together

with the stowage location of such items.

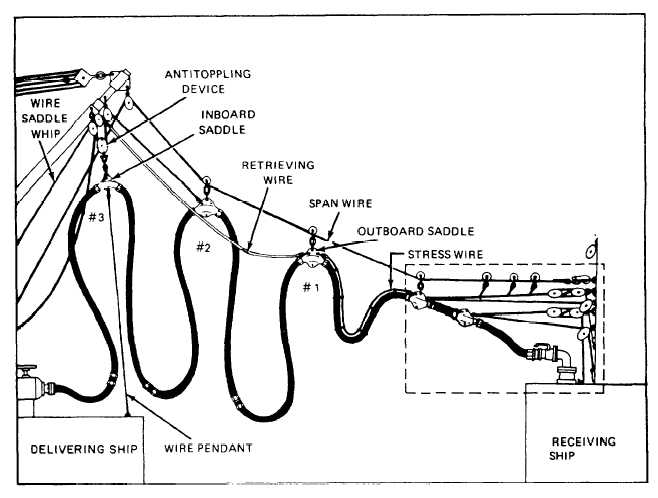

REPLENISHMENT RIGS

LEARNING OBJECTIVE: Identify the

common replenishment at sea and fueling at

sea rigs.

Replenishment at sea is conducted by using a span

wire to support the fuel hose rig between the two ships.

The span-wire rig or close-in method may be used. The

method used is determined by the type of ship

delivering the fuel and the conditions under which the

delivery must be made. The main difference between

the rigs is in the method of extending the hose to the

receiving ship. Of the two, the span wire is preferred.

Ships not equipped to transfer by span wire must do

so by the close-in method.

SPAN-WIRE METHOD

In the span-wire method of fueling at sea, the hose

is carried between ships on a span wire that may be

tensioned or untensioned. The untensioned span wire,

normally is referred to as the conventional span-wire

rig. The tensioned span-wire method is referred to as

STREAM. STREAM rigs are rigged with four saddles

and a hose length of approximately 300 feet. The hose

hangs from trolley blocks that ride along the span wire.

Saddle whips position the hose while fueling, and serve

to retrieve the hose after the fueling operation is

completed.

The span-wire rig (see fig. 4-27) permits ships to

open out from 140 to 180 feet. Such distance is

reasonably safe and makes it fairly easy to maneuver

Figure 4-27.–Fuel stream, single hose with probe.

4-32

|