| |

CHAPTER 6

THE DRY-CLEANING OPERATION

The dry-cleaning operation is another service

activity of the supply department. The supply

officer is responsible for providing dry-cleaning

service on ships where dry-cleaning equipment is

installed. The responsibility for providing this

service is normally assigned to a junior Supply

Corps officer.

Since water damages certain fabrics, some

clothing must be dry cleaned. Dry cleaning is the

process by which you immerse soiled and stained

garments in dry-cleaning solvent in a dry-cleaning

machine. Normally, dry-cleaning equipment is

installed on ships with over 500 personnel;

however, provisions for dry-cleaning equipment

on ships with 100 to 500 personnel are considered

on a case-by-case basis.

DRY-CLEANING PERSONNEL

The number of Ship’s Servicemen and strikers

assigned to the dry-cleaning operation depends on

the workload and the equipment. On carriers and

tenders where the plant is much larger than on

other ships, there may be a supervisor, an assistant

supervisor, and 6 to 10 additional personnel.

The petty officer assigned as supervisor is

responsible for preparing the dry-cleaning

schedule, procuring supplies, training personnel,

operating the plant,

and cooperating with

engineering personnel in maintaining the

equipment. The supervisor assigns personnel to

do the work as efficiently as possible and rotates

them so they can get experience in all the tasks

performed in the plant.

DRY-CLEANING SECURITY

All dry-cleaning personnel are responsible for

maintaining security in the dry-cleaning plant.

Security prevents loss of dry-cleaning articles,

damage to equipment, injury to untrained

personnel, and unauthorized use of equipment

and facilities. The dry-cleaning plant is considered

a Group IV space. Keys should be handled as

outlined in chapter 1 of this manual under Group

IV spaces. Any work done in the dry-cleaning

plant after normal work hours should have the

final approval of the ship’s store officer.

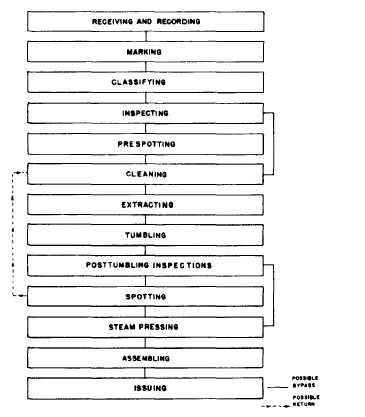

DRY-CLEANING SCHEDULE

As in the laundry, a schedule is necessary for

controlling the delivery, processing, and issuing

of dry cleaning. To prepare such a schedule, start

with a flow chart of all operations through which

articles must pass from the time they are received

until they are ready for issue (fig. 6-1). Then

Figure 6-1.—Dry-cleaning flow chart.

6-1

|