| |

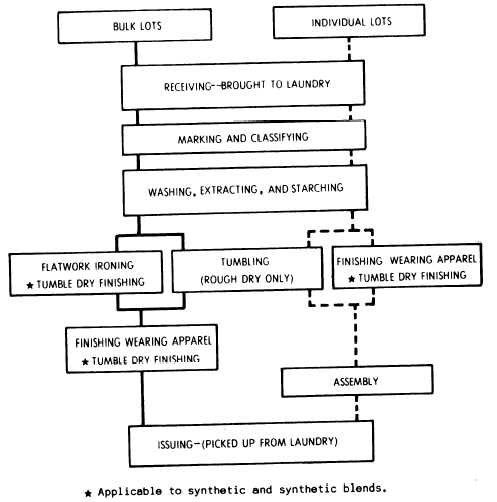

Figure 5-6.—Workflow for a laundry operation.

other white or light-colored fabrics, light cottons

with heavy stains, dark-colored cottons, and so

forth. Items are classified according to the

washing formulas to be used.

HANDLING LOTS

The main problem with handling lots in the

laundry is identification. You need to have a good

system of identification in the ship’s laundry to

prevent loss of clothing during the workflow

process. There may be several personnel handling

the clothing and proper identification is essential.

IDENTIFYING BULK LOTS

The clothing in bulk lots should be delivered

to the laundry already stenciled. Each enlisted

person is responsible for stenciling his or her own

clothing. The laundry petty officer in each division

should accept only properly stenciled clothing.

Both black and white stencil pens usually are

available in the retail store.

Proper stenciling of clothing ensures proper

distribution from the laundry. If the laundry

supervisor runs into problems with lost clothing

and claims, he or she may want to control the

items turned in and return these items to each

person. The laundry petty officer can list all

articles across the top of a sheet of paper and write

the people’s names in a column down the left side

of the sheet. The number of each article sent by

each person should be entered in the box opposite

the name and below the article. When the articles

are returned to the individuals, the names are

checked off the list. If all articles are properly

5-9

|