| |

stenciled before they are sent to the laundry, this

type of control will generally be unnecessary.

Once bulk work is accepted it is the responsi-

bility of the laundry to make sure it is properly

identified from start to finish. You do not have

to identify individual items in bulk lots brought

to the laundry, but you do need to put some type

of marker with each lot so that you can identify

it during any phase of processing. You can make

your own markers, or flags, from a duck fabric.

Cut squares about 8 to 12 inches and hem them.

Then stencil one marker for each division, service

group, or any activity that brings bulk work to

you. When bulk lots are brought to the laundry,

put the proper identification markers on them.

You can use the same markers week after week.

In addition to these markers, the division/

department name should be stenciled on the side

of the bag in case the marker gets lost during the

process.

In the event you are required to split a lot, put

the right markers on every part of it. All markers

remain with lots and portions of lots during the

complete washing and processing cycle. Put the

marker in the washer with the load, and identify

the load on the shell of the washer with chalk.

If it is necessary that you put more than one lot

in the washer to get full capacity, use a proper

size laundry net for the smallest lot. When more

than one net is required for the same lot, use a

marker for each net.

All soiled divisional bulk bags delivered to the

laundry should be kept separate from clean

laundry. In smaller laundries where space is

limited, an effort should be made to have all clean

laundry picked up after it is completed.

IDENTIFYING INDIVIDUAL LOTS

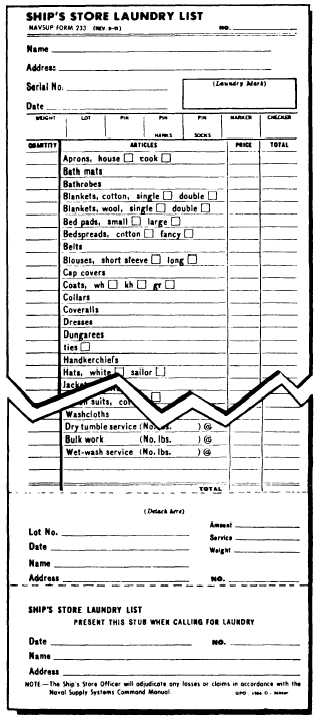

Ship’s laundries use a Ship’s Store Laundry

List, NAVSUP Form 233, so officers and CPOs

may identify what they have sent to the laundry

(fig. 5-7).

Normally, the form contains blanks at the top

for the name of the ship, name of customer, rank

or rate, social security number, date, and laundry

mark. There is usually space for a Customer’s-

Count column and a Laundry-Count column,

aligned with the list of articles.

The customer fills in the lines at the top of the

laundry list, enters the number of each article in

the appropriate block, puts the laundry list with

the laundry, and turns it over to the laundry

receiving clerk.

Figure 5-7.—Ship’s Store Laundry List, NAVSUP Form 233.

In conjunction with the laundry list, laundry

net bags should be used for the purpose of keeping

rough-dry clothing together during the laundry

process. They are open-mesh bags made from

cotton or nylon in which the clothes are placed

5 - 1 0

|