| |

the number of different commodities. In a sec-

tion where one item fills the entire area, the sec-

tion should be stacked to its capacity, leaving only

enough space to “get at” it and permit access for

fire prevention or fire-fighting purposes.

CROSS AISLES.— Cross aisles are passage-

ways at right angles to main aisles. At least two

cross aisles are needed in the standard warehouse

section. Where possible, cross aisles should be laid

out so that they will lead directly to opposing

doors of the warehouse. Most storage operations

are carried on in the cross aisles.

PERSONNEL AISLES.— Personnel aisles are

those used as pedestrian routes only. Personnel

aisles should be held to a minimum. Too many

deprive you of valuable storage space and at the

same time encourage pilferage since they are

usually secluded.

FIRE AISLES.— Fire aisles are necessary in

every depot or storage activity, but should be kept

to a minimum in number and width, since they

waste valuable storage space. It is seldom

necessary to have fire aisles wider than 24 inches.

In many cases they can be eliminated by a simple

change in the location of fire-fighting apparatus.

Fire aisles must be adjacent to windows that can

be used by firemen to gain entrance.

SERVICE AISLES.— Services aisles are nor-

mally used for only special commodities of

material. They provide access to the interiors of

stacks for protective processing, inventory, and

inspection.

Direction of Storage

Use of the fork truck and pallet system makes

direction of storage a significant factor in space

use. Selection of the proper direction of storage

can be invaluable in providing a variety of bay

sizes without increasing the number of working

aisles. At the same time, such planning tends to

spread the volume of traffic equally over all work-

ing aisles, relieving congestion. This concept is

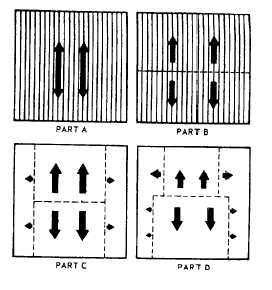

illustrated by the diagrams in figure 7-7 that

develop layout in respect to direction of storage

for a bay 80 square feet, a typical bay for large-

lot storage in a standard warehouse. Using stan-

dard 48- by 48-inch pallets, about 17 pallets can

be stored in each direction.

Single Item Stored Aisle

to Aisle

The simplest but most inflexible disposition

of storage space is storage of a single item aisle

to aisle shown by part A of figure 7-7. This layout

makes no provision for storage of small lot items,

which practically every warehouse has.

Miscellaneous Commodities

Numerous articles are shipped in bales and

consequently should be stored in the same

manner. Some are baled even and solid; others

are irregular and slack. The size of the bale varies

with the commodity. Be careful not to break the

strapping. One broken strap on tightly com-

pressed bales will put extra strain on the other

straps and may cause the bale to break open. Firm

bales can be palletized and piled as safely as cases.

Slack bales that cannot be palletized should be

tiered and tied in with dunnage.

Various commodities such as flour and sugar

are shipped in burlap or waterproof paper con-

tainers. Nails, bolts, or sharp edges should be

eliminated in areas where bagged goods are to be

stored. If these hazards cannot be removed, the

bags should be protected with dunnage. If a bag

is broken, it should be plugged with a piece of

paper and sewn.

Bags containing perishables or “subject to

taint” commodities should be stored on clean, dry

dunnage or pallets. Use separating paper with

such commodities. Keep them away from odorous

commodities—tarred rope, for example.

Figure 7-7.—Principles of working aisle arrangements.

7-20

|