| |

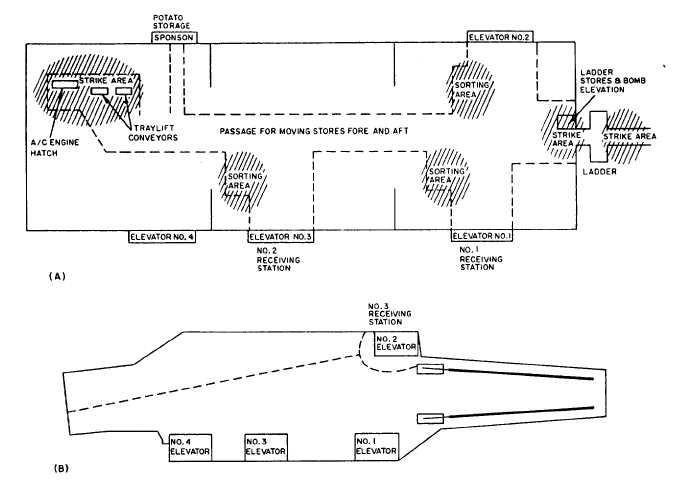

Figure 7-1.—Carrier deck plans (A) hangar deck; (B) flight deck.

replenishment) until the nets are detached from

the transfer rig at the receiving station. At that

moment the stores become the responsibility of

the supply department. They must be removed

from the receiving station as quickly as possible.

The time interval available is the time required

for the hook to travel to the transferring ship, pick

up a loaded net, and return—a matter of

moments. Material received by helicopter must

be moved into position on the elevator quickly

and the elevator promptly lowered to the hangar

deck, cleared of stores, and promptly raised to

the flight deck for the next load.

SORTING STATIONS.— The second group

is composed of the sorting or segregation stations,

where the material is separated by type and

storage destination. These stations may be located

at any point, depending upon local conditions.

Sorting necessarily requires a fair amount of

space, especially since there may be temporary

delays while unit loads of one item are assembled.

The main consideration in assigning locations for

sorting stations must be that no time or effort is

wasted. If the storerooms are located in other

parts of the ship, sorting must be done on the

hangar deck. Material received by helicopter on

the flight deck is usually shunted promptly to a

hangar deck sorting station.

Some ships are designed so that foodservice

storerooms are accessible from the messdeck. On

these ships, provisions may be shunted directly

below to the messdeck before sorting.

STRIKE STATIONS.— The strike stations,

the third group, are the access hatches where the

material is moved below decks. Included in this

group are the ammunition

where pallets are lowered

and hatches where material

hand by sliding on board or

or belts.

elevators, hatches

by electric hoists,

is passed down by

down metal chutes

7-11

|