| |

CHAPTER 6

RECEIPTS AND EXPENDITURES

In chapter 5 we discussed the various ways that

you can order material and services. This chapter

pertains to the receipt and expenditure of the

material that you have ordered. The various types

of receipt documentation, the payment of dealers’

bills, and the preparation of any documents that

are missing from the material will be explained.

MATERIAL RECEIPTS

Material receipts are classified by type. Think

of receipts in a larger context; one that includes

the initial handling of stores, the verification of

packages and papers, the processing of receipt

papers, and the inspection and disposition of

incoming stores.

By regulation, the supply officer is responsible

for all the functions listed previously, but the

actual handling of the functions is carried out by

the leading Storekeeper (SK) in charge of the

storerooms. This SK is responsible for supervising

the handling of all incoming stores except those

for which other SKs may be personally account-

able, such as subsistence items. The SK also

sees that stores are brought aboard, properly

identified, checked, sorted, and distributed to the

supply department storerooms or ship’s depart-

ments, and that receipt documents are properly

processed and turned in to the supply office. The

duty SK must make sure material delivered after

normal working hours, on weekends, or on

holidays is received, identified, inspected, and

placed in the designated receiving area. If the

receipt document is marked for direct turnover

(DTO), the material should be turned over to the

appropriate department. The duty SK must also

make sure receipt documents are properly an-

notated and given to the leading storeroom SK

the following workday. In performing these

duties, the leading SK exercises direction over

other SKs and over working parties handling the

incoming stores.

PREPARATION FOR RECEIPT

OF MATERIAL

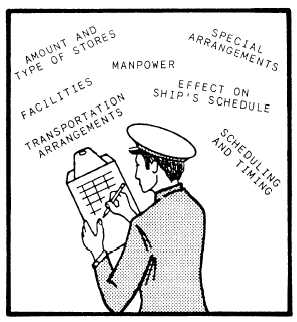

The narrative and illustration (fig. 6-1) in this

section are intended to provide the afloat supply

officer and senior enlisted personnel in the supply

department with guidelines for the preparation of

material delivery, receipt, and eventual storage.

In United States Ports

To facilitate effective planning of depart-

mental and shipboard work, the supply officer

and senior SKs must coordinate the scheduling of

shipboard receipt between the shipping activity

and the in-port routine and operating schedule of

the ship. Arrangements should be made to receive

stores during normal working hours, whenever

practical, and well in advance of anticipated ship

movement. If working party assistance from other

departments will be required to load stores, the

Figure 6-1.—Factors in planning stores loading.

6-1

|